| 项目 | 参数 | 备注 |

| 机器名称 | 重式/六重式液压精密矫平机 | |

| 机器型号 | JZ-YY-4000 | |

| 材料最大宽度 | 4000mm | |

| 矫平厚度范围 | 1.0-60mm | 额定板厚(1.0-60mm) |

| 矫平辊直径 | 12-260mm | |

| 矫平辊辊表面硬度 | HRC 60-62 | 中频淬火 |

| 矫平辊辊表淬层深 | ≈1-5mm | |

| 输送平台 | 选配 | |

| 最大矫平力 | 12000kN | |

| 最小矫平工件 | 30-400mm | |

| 最大定型行程 | 200mm | |

| 油缸工作压力 | 20MPa | |

| 总功率 | 6kW-150kW | |

| 用电制式 | 三相交流电380V(±15%) 50HZ(±2%) | |

| 单相交流电 | 220V(±15%) 50HZ(±2%) | |

| 相对湿度 | ≤90% | |

|

矫平辊加工工艺 (包含表面热、冷加工) |

握造-正火-回火-毛探检验-粗车-探伤检验-调质-精车-表淬-回火-粗磨-精磨镀铬-精磨精磨度±0.01mm |

完全按冶金轧辊 加工工艺 |

| 矫平能力 | 屈服强度≤460-1180MPa | |

| 整平辊 | 19pcs(上9/下10) | 特殊轴承钢 |

| 整平方式 | 触摸屏液压调节 | 西门子 |

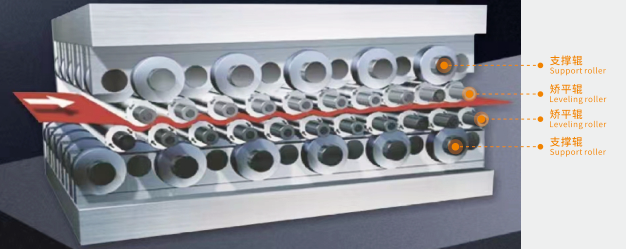

4-HIGH LEVELING PRINCIPLE |

6-HIGH LEVELING PRINCIPLE |

|

Based on "Bauschinger effect", metal blanks were repeatedly twisted to make metal fiber gradually consistent, eliminate internal stress, restore and improve the flatness of work-pieces. Suitable for construction machinery, metallurgy, vehicles, metal structures, ships, pressure vessels, chemical machinery and other manufacturing industries as well as metal material warehousing, metal plate distribution etc. industry. It not only can be used separately but also used in metal plate formingline, coil feeding line etc.

It's concentric of the bearings and support roller so as to guaranteed very precise and consistent running of the support rollers and increase leveling roller's rigidity, meanwhile, it's designed more wider of the support rollers than competitors, then it can well improve the scratch on material's surface caused by support rollers. |

The deflection force generated during the operation of the leveling roller and assistant roller are borne by the support rollers. Multiple sets of support rollers work together to greatly improve the stress state of the leveling roller and facilitate the conduction of leveling, pressure.

Leveling roller material is smelted and forged high-grade alloy steel Gcr15. Roller body hardness is HRC28-32" after heat treatment, hardened layer depth is:2-4mm. The leveling surface is chromium plated with a coating, depth of 0.1-0.2ram, surface smoothness reaches 0.8-0.2, surface hardness HRC60-64,the mechanical properties of the leveling roller after processing have reached tensile strength≤900N/mm, yield limit ≤800N/mm, elongation coefficient ≥15%, Impact resistance value≥70N-M/cm.

When the support roller bears the deflection force, it is transmitted to the leveling roller through the assistant roller. The assistant roller has the same length as the leveling roller, but its diameter is slightly smaller, so that the plate becomes flat during the by uneven distribution of direct contact between the support roller and the leveling rollers. leveling process. The force is evenly distributed along the entire plate width, thus avoiding the indentation phenomenon caused

|

|

|